|

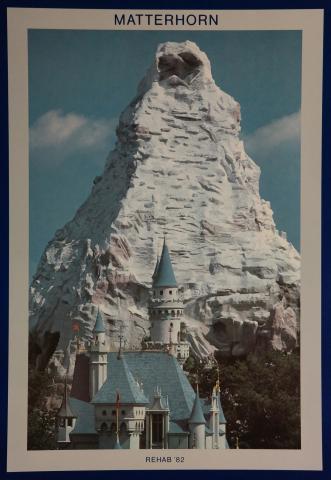

In part 6 we wrap up the creative genius that went into creating the Matterhorn Bobsleds! Imagineers put a pool of water in the attraction to cool down the brake pads. Once you make it up to the peak - it is a free fall the whole way down!! Matterhorn uses gravity to do its work and water to cool it all off. Believe it or not, with Matterhorn's reputation of being a very rough ride, this two-wheel system was actually designed to make it much smoother and unlike traditional top track roller coasters. The Matterhorn's main mechanism exists in between the tracks actually making it a horizontal ride system. The next time you get on the Matterhorn or while waiting in line to ride, look below the sled and you'll see two different sets of wheels. Take note that you're also looking at innovation that changed the theme park industry forever because this was the first of it's kind. But it was far from being the last; this ride system would end up being replicated in nearly every theme park in every country around the world. Yet another thing that was invented in Walt's Disneyland that has found its way all around the world. The inspiration from Disneyland never stops making its way into various projects that Disney and non-Disney folks work on till this day. Probably one of the greatest tricks of the Matterhorn is that every single day it fools people to believe there's a mountain covered in snow, that they know that they can go in and have one of two adventures. When the Matterhorn was finally finished at a cost of $1.5 million dollars, ($15 million today), Admiral Joe Fowler said to Walt Disney, "next time we have to build a mountain, let's let God do it."

Thank you uncle Walt for creating the Matterhorn Bobsleds and the idea that changed not only Disneyland but theme parks all around the world forever. Wow part 5 of this amazing structure! Because the Matterhorn had such a tight Inner Space there was no way to build a wooden roller coaster where essentially you can go as far and as long and as high as you want. You don't have the flexibility of endless turns; that's where the steel tube came into play. With an early sketch of what Matterhorn was going to look like, imagineering was given the task of figuring out how to lay out a track inside of the Matterhorn. But as pointed out before, there's over 2100 steel girders inside, the track would not only need to fit inside the mountain, but it would need to avoid every vertical and horizontal support that kept the mountain standing. Imagine having 10 months to try to figure out how to put a roller coaster inside of a sketch, looking at the architectural blueprint and try to dodge every single support beam that would make the mountain stand! With two roller coaster tracks, the most practical idea was to design a lift that would take guests up as high as possible inside of the Matterhorn, for a Fantasyland side and a Tomorrowland side. An absolutely amazing feat of architecture and design if you consider that this is an incredibly crowded space. That's where the tubular steel comes in. A wood roller coaster could never make all of the turns and the banks and the curves that were needed to get gas from the lift down to each side of the Matterhorn and get dropped back off in nearly the same spot. The only way to bend the tracks inside of this incredibly tight footprint was to use something that could bend. Steel became a part of the Matterhorn because steel can be heated and curved in any direction needed to create all the banks, inclines, twists and turns required to get two sets of track inside of this footprint. With older traditional roller coasters, they're designed more like a train where a cart rides on top of the track and the train track takes you on all kinds of twists and turns. But the turns can't be that tight and couldn't exist inside of a mountain nor would a train be able to replicate the smoothness that one would feel if they were actually going down a mountain on a bobsled through snow and ice. It would need to be a very smooth ride. The steel tubes created another problem, they realized they couldn't run steel wheels on a steel rail because it would be way too bumpy and way too noisy. Imagineers figured out a solution using rubber and they would run tests on small sections. They quickly realized that a traditional rubber wheel wouldn't last and keep up with the demand of this roller coaster. It was then that they came up with the idea of using polyurethane, a relatively new plastic in manufacturing in America that originated from Germany in World War II.

Disney began working in partnership with Dupont and they were able to figure out a proprietary urethane wheel that would actually ride on this steel beam. The polyurethane wheel rolls on top of the steel tube giving a smooth ride, while all of the lifting is done on the mechanism that hits the horizontal plane. As a result there's actually two sets of wheels. The vertical wheel and then the horizontal wheel does all of the lifting on the incline and helps with the braking process. Stay close for part 6! The Shah of Iran and Empress Farah enjoy a bobsled ride with Disneyland hostess Donna Jackson and Walt. April 1962

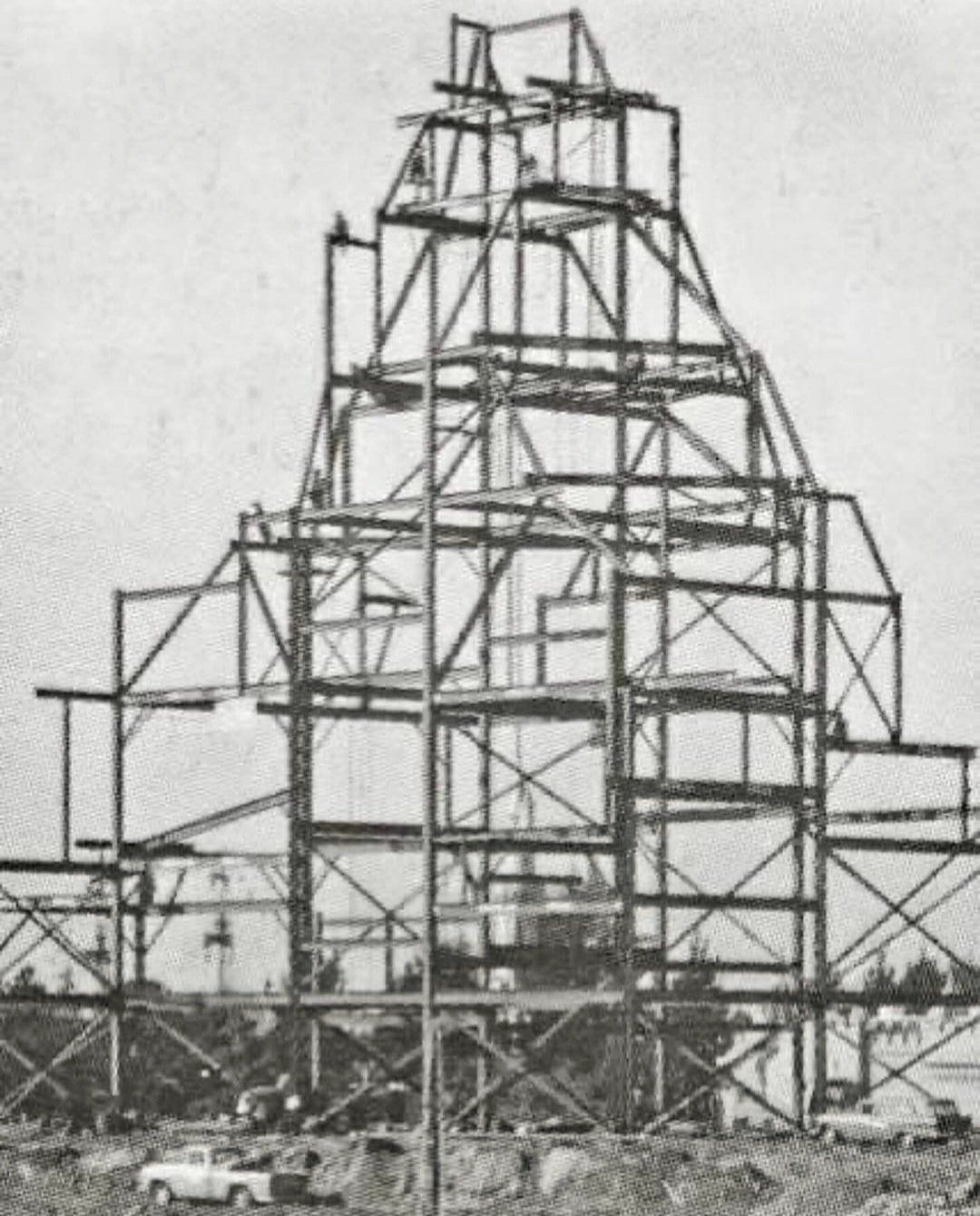

Disney had a very backwards way of building the Matterhorn. They built the mountain first, had the exterior completely planned out then Disney imagineering was given the quest to do the problem solving of building the roller coaster inside of the already existing footprint of the mountain. One would normally think you would build a roller coaster and then build a mountain around it. Since it had never been done before they did it the opposite way. Disneyland's Matterhorn is 100th scale of Switzerland's Matterhorn which sits 14,700 feet in the air. Disney's Matterhorn is 147 feet and made up of over 2100 steel girders that make the frame and give mountain its strength. Nearly all 2100 were different sizes and lengths to create this jigsaw organic looking mountain. The a very well hidden 15 story building's exterior was originally made out of plywood that was then painted and sculpted on the outside. That left for Aero development and Disney imagineers a very intricate puzzle of space to try to put in not just one, but two roller coaster tracks! Admiral Joe Fowler knew that this would be something that would be in high demand and he also knew that Disney could use a lot more capacity for guests at Disneyland. Putting in two tracks theoretically would mean twice as many guests could enjoy Matterhorn mountain. This is something they've gotten away from in recent years with other roller coasters where they do a switch track. Instead of actually building two different tracks operating at the same time, Disney figured out that it's easier to make two different loading areas. Like what we see at Big Thunder Mountain or the Incredicoaster, by using one track and loading guests in two different locations. It's a lot more affordable than building the ride twice. And it gives you the capacity that you need because you're always loading a train or cart to get on that track. More to come in part 5....

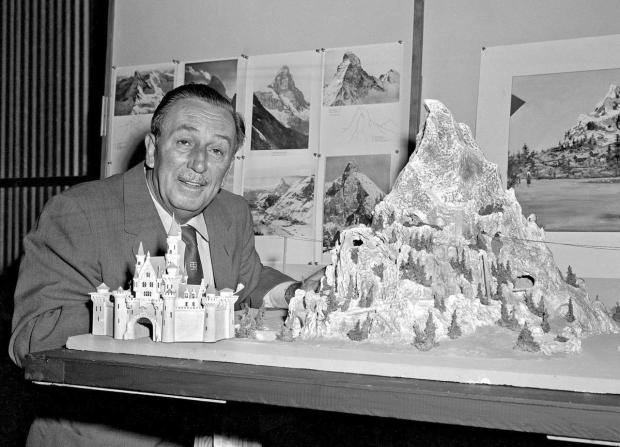

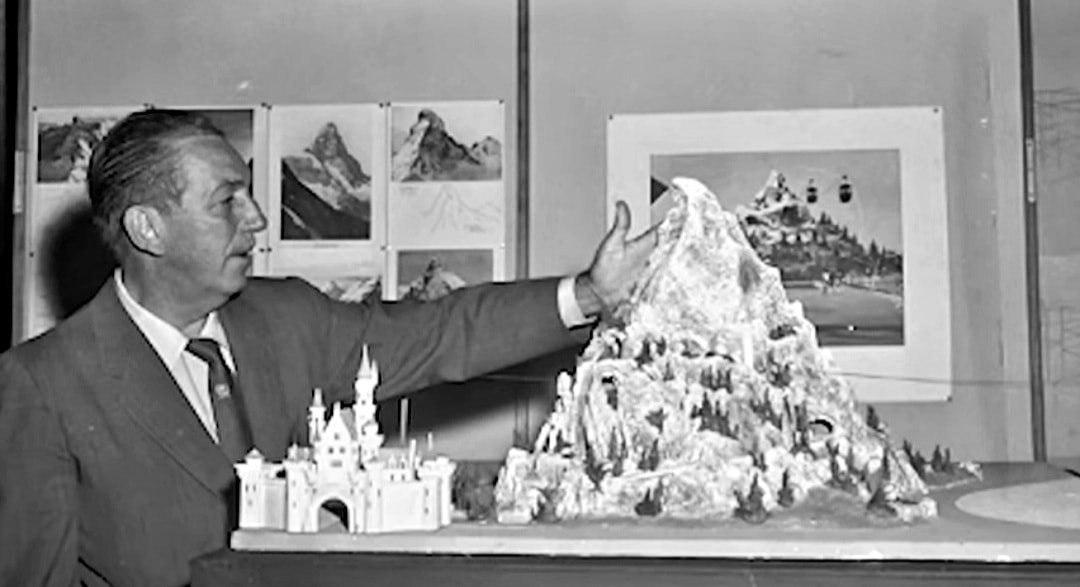

When Harriet Burns made the very first model of the Matterhorn, it was one foot high. She made it like a birthday cake where it was done in layers, so that if one layer didn't get approved, it could be removed, redone, re-sculpted and put back together. She would recreate this process over and over again until finally they would have an approved rough sketch of the Matterhorn built in this birthday cake style out of clay. The large model was then cast and that's what you see today replicated from a model that started out being made like a birthday cake. If you look at the Matterhorn now, you can see that there are various different layers to it, then the top peak is made up of about three layers each layer gets incredibly smaller creating the force perspective making this feel a lot taller than what it is. The height of the Matterhorn is pretty fascinating. There's a lot of steel buildings that are constructed in a way where all the steel beams are the exact same size because you're essentially erecting a grid up into the air, but with the Matterhorn all of the various still beams (and there were a lot of them) were various different sizes. This was like constructing a jigsaw. To think that this right here it's actually a building, a 15-story building, built in so many different jig Jags and seesaw pieces. But to our eye, it really does look like a snow-covered Mountain! Part 4 coming soon!

|

Categories

All

Archives

July 2024

|

RSS Feed

RSS Feed